Call Us Now

+86 18706432618

|

Lines: |

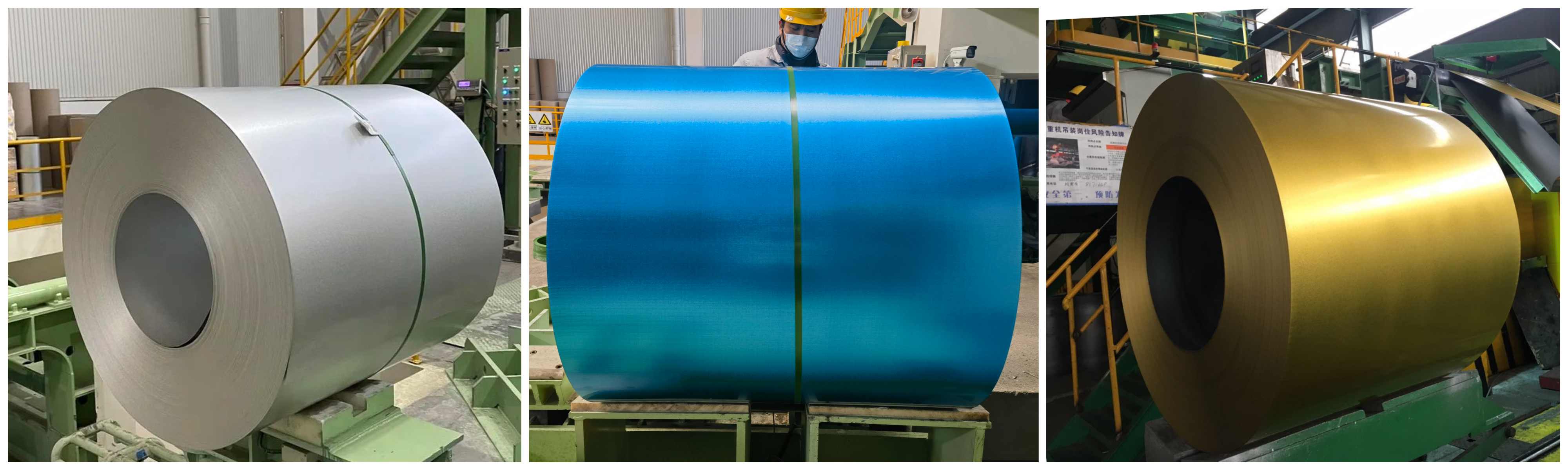

Galvalume Steel Coil |

|

Thickness (mm): |

TC 0.2-1.2 |

|

Width (mm): |

800-1260 |

|

Coil weight (MT): |

3.0-8.0 |

|

Zinc coating: |

30-220 g/㎡ |

|

Painting: |

0.5-1.5μm |

|

Coating Composition: |

55% Aluminum - 43.5% Zinc - 1.5% Silicon |

|

Strength: |

G250/G280/G300/G350/G550/ DX51D/DX52D |

|

MOQ: |

32 tons per size |

|

Payment term: |

T/T; L/C at sight |

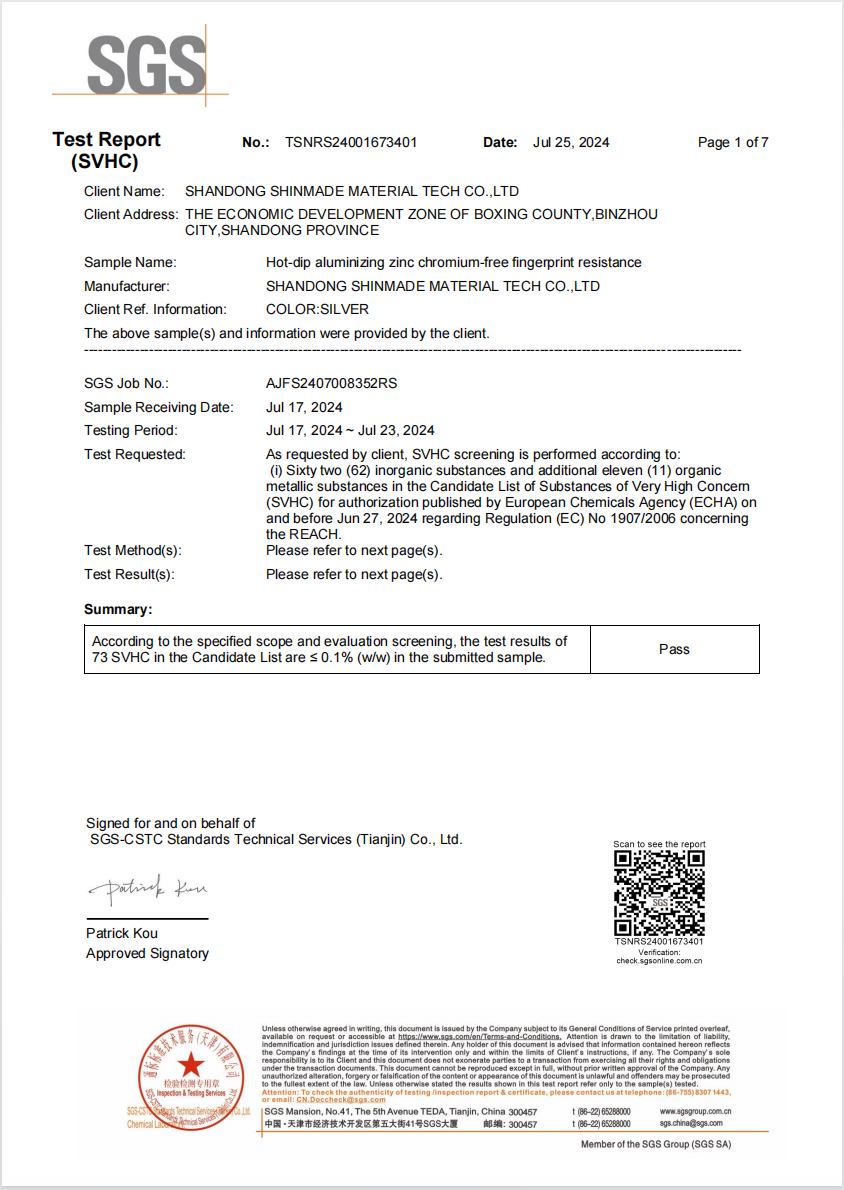

Product Advantages

Small dendrites space distance

With unique formula of the coating and control of coating thickness, the dendrite spacing of Shinmade galvalume steel is 10-15μm under electron microscopy, and the corrosion resistance of the product is excellent.

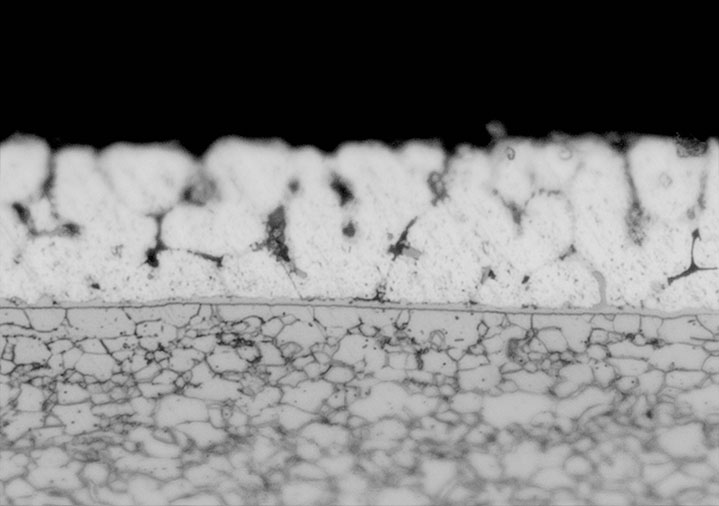

Coating cross-sectional structure - optical microstructure

The coating structure of Shinmade’s products is a staggered skeleton, which has good density and can prevent the intrusion of rainwater and other corrosive media, and that is why the product has good corrosion resistance. If the coating structure is bamboo-like, which means the coating layer is not dense enough and the corrosion resistance can be poor.

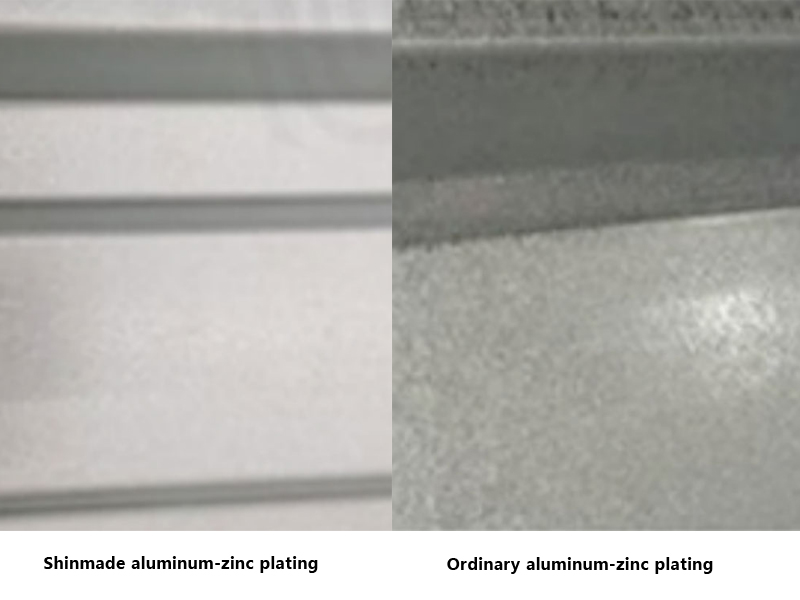

Small-sized and uniform spangle

The stability of crystallization determines the size and uniformity of spangles. The spangles are precisely controlled under the combined effects of the steel strip temperature, zinc liquid temperature, surface roughness, post-plating cooling, and special coating formula. The diameter of the spangle of Shinmade's galvalume is controlled between 0.5-3mm, which means the spangles are small-sized and uniform, and the appearance effect is more stable.

Chromate/Passivation+AFP

We adopt double-coating and baking process for post-treatment, which means we first to passivate, dry and cool the sheets, next to apply AFP coating on the sheets and dry and cool. The AFP film is thicker and cured better, so the processing lubricity is relatively better.

|

Construction industry: |

Roofs, exterior walls, color - coated substrates, garage doors, fences, shutters, ventilation ducts of civil and industrial buildings, etc. |

|

Industrial instrumentation: |

Electric control cabinets, industrial freezers, vending machines, etc. |

|

Home appliance industry: |

Washing machines, refrigerators, televisions, air conditioners, ovens, outer covers of ventilation systems, explosion - proof strip steel, solar water heaters, electrical components, etc. |

|

Other industries: |

Automobile mufflers, heat shields for exhaust pipes and catalytic converters, parts at the bottom of automobile bodies, highway signs, car horns, small hardware, etc. |

Shinmade owns 2 galvalume production lines with an annual designed production capacity of 550,000 tons.

1、Siemens electrical control system

2、German EMG correction CPC/EPC system

3、9-stage cleaning system

4、Ultra-long horizontal annealing furnace

5、Advanced air knife system

6、Online X-Ray coating thickness measurement gauge

7、Wet finishing design (skin- pass strength 5000kN)

8、Double-bending and tension-leveling ( wet leveling and straightening )process

9、Double coating (passivate and AFP) and baking configuration

Q: What types of steel coils do you supply?

We offer a wide range of coils including GL, PPGL, and CR.

Q: Can I customize the coil specifications ?

Yes. We support full customization of thickness, width, coating weight, paint color, and surface finish based on your specific requirements.

Q: What is the minimum order quantity ?

Our standard MOQ is usually 32 tons per specification.

Q: What coating and painting systems do you offer?

We provide Al-Zn coatings with various paint systems including PE, SMP, HDP, and PVDF. The choice depends on your intended application.

Q: Do you provide samples before placing bulk orders?

Yes. We can provide free samples.

Q: How long can your painted coils last in outdoor conditions?

Our GL coils can last 20–30 years depending on environmental exposure.

Click to learn more:

Hot Tags : Highly Corrosion Resistant Galvalume Steel Coil Zn-Al Alloy Coated Steel Sheet Aluminum-zinc Coated Steel Coil Aluminum-Zinc Alloy Coated Steel Plate Hot-dipped Galvalume Steel Coil Galvalume (GL) Steel Coils

Hot Tags : Galvalume Steel Coil Anti-Finger Print Steel Coil Fingerprint Resistant Galvalume Steel Coil Fingerprint Resistant Aluminium-Zinc Steel Coil Fingerprint-Resistant Galvanized Steel Sheet Fingerprint resistant galvanized aluminum steel coil

Scan To Wechat